This User's Guide applies to the currently released Vers TSm v8 models. For earlier versions, the User's Guide can be found at this link.

Purpose.

The Vers TSm sensor is used to determine tool height and diameter. CNC milling machine generates coordinates when the tool touchs the VersTSm measurement pad and uses them to calculate the height and diameter of the tool. The device can be used with various CNC systems: LinuxCNC, Mach3, embedded systems on industrial machines, etc.

What's new in v8

1. Tungsten carbide on pin-ball contacts.

2. Unidirectional repeatability < 0.002 mm.

3. Permitted deviation stylus in XY ±4mm.

4. Two types of output signal NPN and PNP are available for selection.

5. Protection against short circuits of the output to power or ground, from power reversal.

Specifications.

Unidirectional repeatability | < 0.002 mm |

Search directions | ±X, ±Y, -Z |

Permitted deviation of the measuring pad in XYZ directions | ±4mm |

Contact force | min 0.5N max 2N |

Diameter and overall height | D=28.8mm, H=40mm |

Diameter* and height of the ceramic pad | D=10mm, h=2.5mm |

Power supply | +5v...+24v |

Current сonsumption | <4mA |

Dust protection | Yes |

Splash protection | Yes |

Adjustability | Yes |

Possibility to measure tool diameter | Yes |

*Diameter 9.98 ±0.02mm, cylindrical and planar irregularity <2µm

Installation.

![]() Placement Vesr TSm is recommended to be chosen so that the entire surface of the ceramic platform of the device is in the working area of the machine, with an indent from the boundaries = the maximum diameter of the tool being measured + 2mm.

Placement Vesr TSm is recommended to be chosen so that the entire surface of the ceramic platform of the device is in the working area of the machine, with an indent from the boundaries = the maximum diameter of the tool being measured + 2mm.

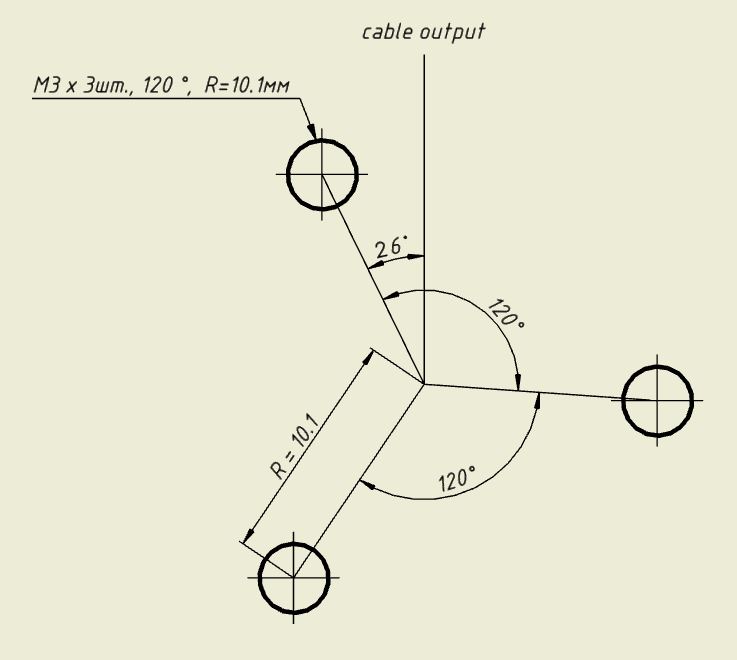

The device is fixed to the machine body with three M3 screws. Three threaded holes are prefabricated in the machine body:

Adjustment.

Before starting the measurement, it is necessary to adjust the device. As a result of the adjustment, the surface of the measuring platform should become parallel to the XY plane.

![]() The indicator should be sensitive to a weak effect of 0.3-0.5N (for example, most lever indicators have this property).

The indicator should be sensitive to a weak effect of 0.3-0.5N (for example, most lever indicators have this property).

For adjustment, three points are selected at the measuring pad (shown with red crosses) approximately at the edge of the site in the direction of the adjustment holes. The indicator is set in the spindle (you will need to moving the spindle in XY coordinates), the stylus of the indicator is located to measure the deviations in height. The results of the indicator must have to the same values in these three selected points. For adjustment, a 2mm hex key is used from the kit, both screwing in and loosening of the adjustment screws located inside the holes, closed with elastic bands. The key is recommended to hold for a short lever, so as not to develop excessive force when screwing.

Connection.

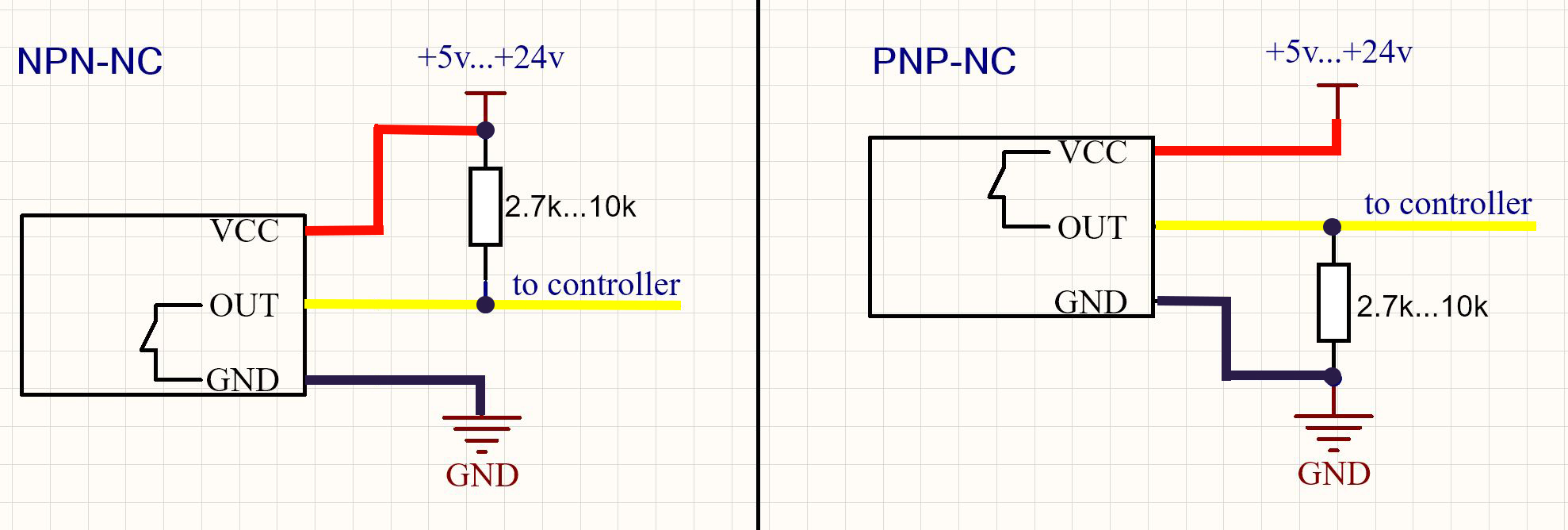

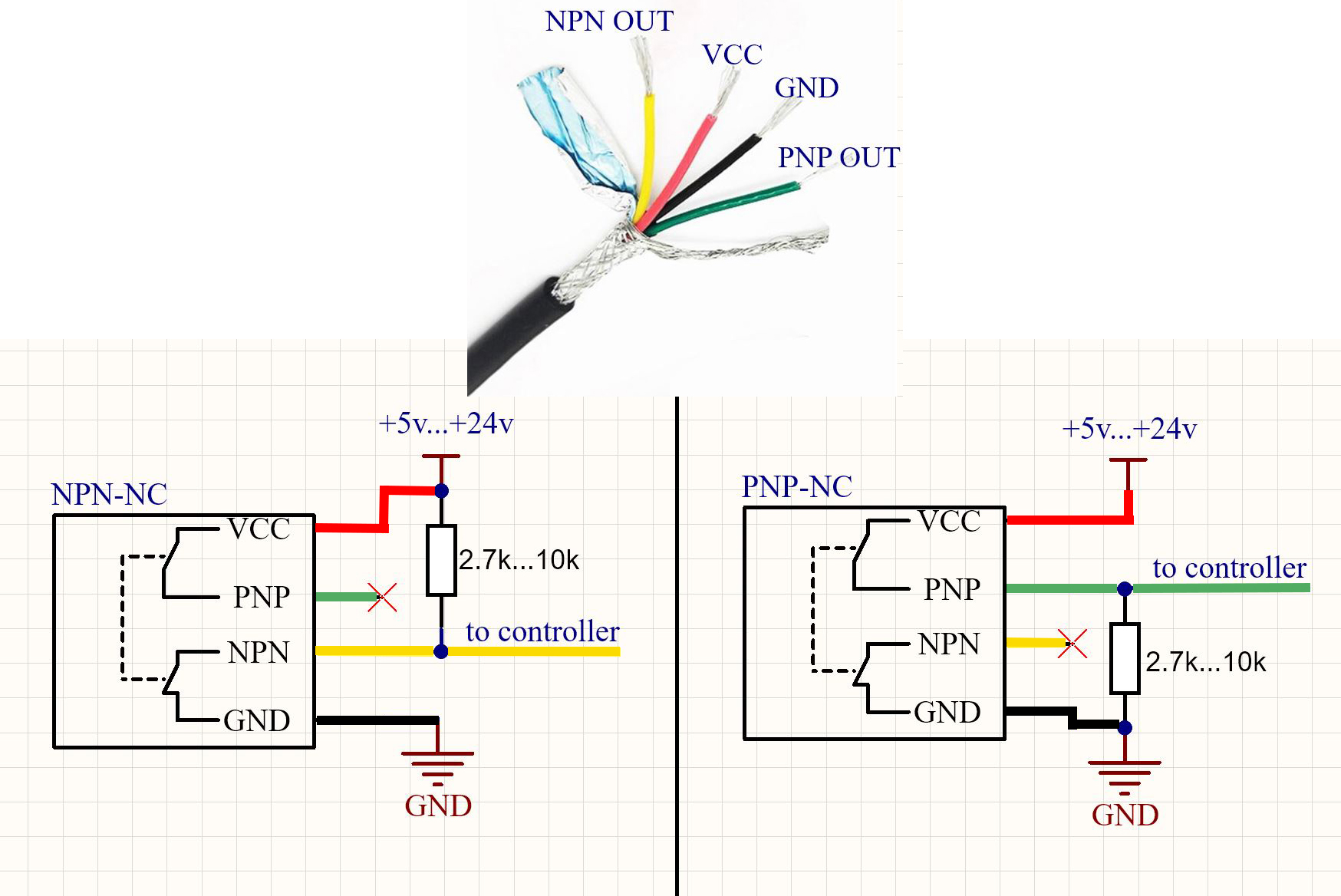

Sensor designed with NPN and PNP outputs, it has polarity reversal protection, protection against short circuits of the output to power and ground.

For Vers TSm v8: NPN or PNP output is selected by the customer during the checkout process (the color of the wires inside the cable corresponds to the colors of the connections in the scheme)

Starting with Vers TSm v8.1, all sensors are equipped with both types of outputs simultaneously. NPN output on yellow wire, PNP output on green wire

Using.

There is software ProbeScreen in free access for convenient work with probe in the LinuxCNC,

Probe Wizard - in the Mach3 system.