This "User's Guide" refers to Vers WL models v.3.1 and below.

Purpose.

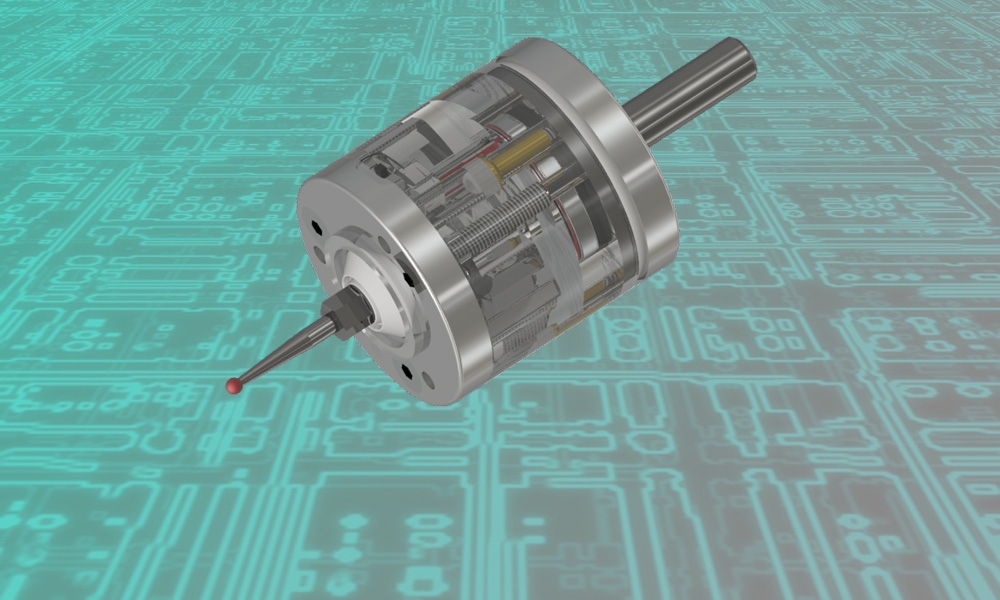

Wireless touch probe VersWL is designed to determine the coordinates and measurements of the installed workpiece and to check the dimensions of the finished parts on a CNC milling machine. The device can be used with various CNC systems: LinuxCNC, Mach3, embedded systems on industrial machines, etc. The device is connected to the CNC system via a radio channel at a frequency of 2.4 GHz. The transmitter is integrated inside the probe. The receiver is supplied as a separate PCB board, connected to the input of the CNC system (see section Connection).

Specifications.

Unidirectional repeatability | < 0.003 mm |

Search directions | ±X, ±Y, -Z |

Stylus deflection in XYZ directions | ±4mm |

Contact force in XY | min 0.5N max 0.8N |

Contact force in Z | 2N |

Delay in the radio channel | < 2 ms |

Error detection delay in the radio channel | < 0.33 s |

Power supply of probe (transmitter) | CR2032 3v |

Current сonsumption of probe (transmitter) | <0,6mA |

Power supply of receiver | 5-12v |

Current сonsumption of receiver | 35 mA |

Radius of the radio channel | 6 m |

Radio frequency | 2,4 GHz |

________________

* All sizes are for reference. The diameter of the ball (tip of the stylus) is approximate, in fact it can differ from the specified within ± 0.02 mm, spherical irregularity <0.003 mm.

Adjustment.

It is necessary to adjust the probe before starting the measurement. The probe is installed in the spindle, a check indicator is placed near to it (Fig. 1)

The indicator should be sensitive to a weak effect of 0.3-0.5N (for example, most lever indicators have this property).

The axis of the spindle is rotated by hand and the amplitude of the deflection of the stylus ball from the axis of rotation is controlled by the indicator.

Fig.1

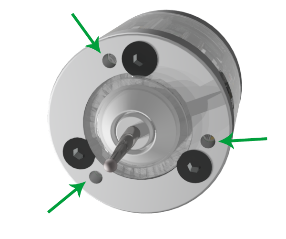

The deviation is eliminated by turning the adjusting screws M2.5 (the screws are recessed into the holes indicated by the green arrows in Fig. 2) with a 2mm hex key from the kit. When adjusting, both tightening and loosening of the screws are used.

Fig.2

It is recommended to hold for a short lever of the key , so as not to develop excessive force (Fig. 3). It will be necessary to perform several cycles of spindle axis rotation--control-- adjustment in order to achieve a minimum deviation acceptable for a particular measurement.

Fig.3

Connection.

![]() The maximum limit supply voltage of the receiver is 12 volts! Recommended 5 v.

The maximum limit supply voltage of the receiver is 12 volts! Recommended 5 v.

![]() Be careful! Failure to observe the polarity of the power supply will damage the receiver!

Be careful! Failure to observe the polarity of the power supply will damage the receiver!

![]() The VersWL consists of 2 parts: a probe (with a built-in transmitter) and a receiver board (pictured below). When the receiver is turned OFF, the probe is always in deep sleep, the awakening takes place automatically within 15 seconds. after switching ON the receiver.

The VersWL consists of 2 parts: a probe (with a built-in transmitter) and a receiver board (pictured below). When the receiver is turned OFF, the probe is always in deep sleep, the awakening takes place automatically within 15 seconds. after switching ON the receiver.

Functions of switches and pinout of the receiver connector:

«Time before sleep» specifies the interval of inactivity of the probe, through which the probe will automatically enter sleep mode. Exit from sleep mode - by pressing the stylus.

«Radio frequency» sets the frequency subband of the 2.4GHz channel.

«mode» selects between a normally closed and a normally open connection circuit.

«npn pnp» selects between npn and pnp the connection scheme.

The switch on the probe is used to turn the device ON and OFF

The CR2032 battery (3 v) is installed with a positive "+" contact to the outside, as shown in the picture:

![]() Be careful! Failure to observe the polarity of the power supply can cause the probe to malfunction.

Be careful! Failure to observe the polarity of the power supply can cause the probe to malfunction.

Switches «mode» and «npn pnp» selects one of the 4 circuits of the receiver connection

Using.

There is software ProbeScreen and Auto Tool Measurement in free access for convenient work with probe in the LinuxCNC(ver.2.6 and higher),

Probe Wizard - in the Mach3 system.